Terex Donates Diesel Training Equipment to Â鶹ÉçTech in Denver

Over $110,000 of new training equipment arrives at Â鶹ÉçTech’s Denver campus, courtesy of Terex Corporation. Terex, a global manufacturer of lifting and material processing products and services, works directly with Â鶹ÉçTech to promote career opportunities for graduates from the Diesel Technician program.

Â鶹ÉçTech and Terex have introduced an internship program that could provide a pathway for students nearing graduation to build their careers. Terex is also working with Â鶹ÉçTech campuses in five other states – Connecticut, Indiana, New Jersey, Tennessee and Texas. Their goal is to identify talented candidates for entry-level diesel technician positions across the country.

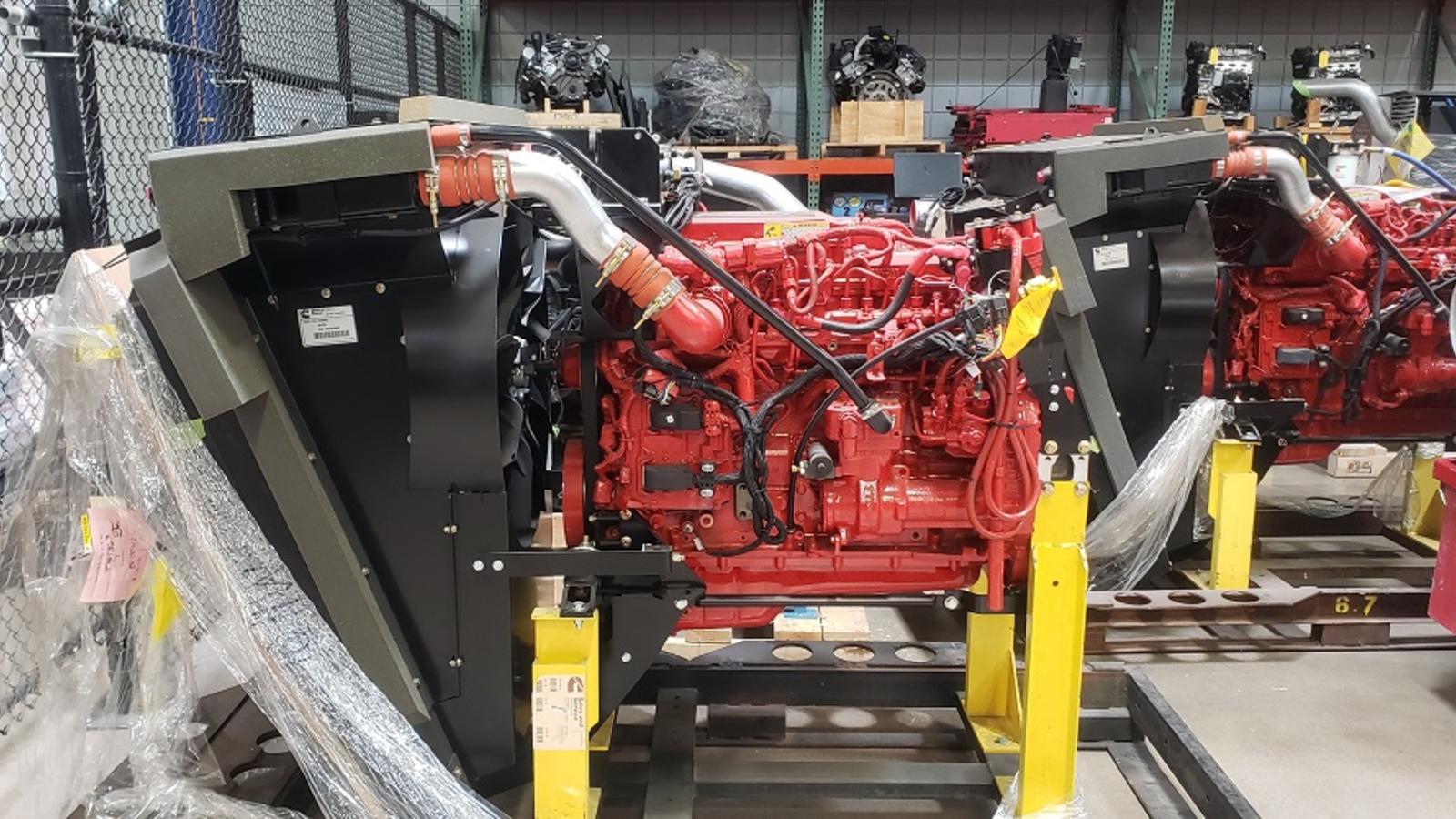

The Cummins 6.7 Liter Diesel 6-cylinder engine model line began in 2007, and has enjoyed immense success as a reliable long-haul engine. This is a right side of the power unit, with the turbocharger in full-view.

The left-side view of the Cummins 6.7 Liter Diesel 6-cylinder engine. Towards the top of the motor, we see the fuel rail has six fuel delivery lines. These lines each terminate at a dedicated injector for the six inline cylinders.

The After-Treatment Emissions System is Cummins’ way of addressing the rigorous emission regulations, reliability and efficiency levels expected of a clean-running diesel powertrain system. This system combines selective catalytic reduction (SCR) system technologies as well as a diesel particulate filter (DPF) into a modular design solution.

The power and torque output from engines like the Cummins 6.7 Liter diesel needs to be reliably transferred to the wheels to move big vehicles safely. Differentials like the models above were supplied by Terex for students to learn about, and maintain, the other end of the powertrain.

- Tags

- diesel technology,

- clean diesel